Repeating an Error

This past weekend, I repeated an error that I had made a long time ago (maybe 30 years in the past) and yet had somehow forgotten the lesson I had learned. Humans are like that. We are not perfect, which is why it is so important that we create good systems to help remind us of those things we should avoid, things we should check, and things we should remember (or should have remembered).

In brief, the problem I failed to remember is that we cannot depend on the forward voltage drop of a diode, when that diode is not operating at or near its rated current.

For a quick (and very dirty) little circuit I was building, I needed to drop a +5V rail down to a voltage between about 2.8 to 3.5VDC. “No problem,” I stupidly thought. “”I’ll throw a couple of 1N4002 diodes in series, and drop that 5V rail down.” The downstream circuit needed only about 20mA (0.020A) so I was not worried about power dissipation in the diodes or any other components or wiring.

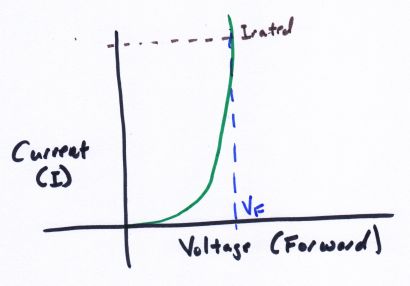

When we look at a diode voltage-versus-current specification, we often draw it this way:

The amount of current you can pull through the diode at the same VF (Forward Voltage across the diode) is nearly a vertical line. This means a 1Ampere rated diode will show about the same forward voltage at 0.75Amps. But if you are operating at a tiny fraction of that current, the forward voltage drop is much, much smaller.

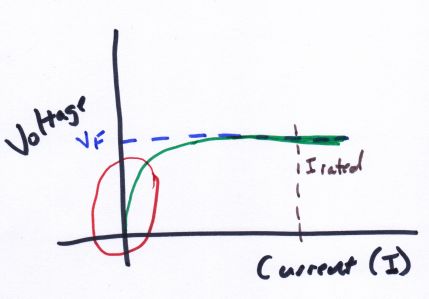

One way to make this more obvious is to swap the voltage and current axes on the plot. Suddenly, it is obvious that the voltage across the diode rises or falls dramatically in the region well below the rated current.

A diode with very little current flowing, also has almost no voltage drop across it. Therefore, the low current of my downstream circuit (which meant I did not need to worry about power-dissipation) also meant that the 3 diode stack was dropping much less voltage than I had expected. Doh! Adding to the problem, the incoming +5V rail was much closer to the maximum 5.25V specification limit.

Fortunately, an easy fix was available using common parts. An LM317 regulator plus a couple of resistors gave me a stable, accurate 3.0V rail to feed the downstream circuit. It required about the same total number of components, so I don’t know why I didn’t think to start there. Maybe my simple mind had become stuck in an old rut or maybe I knew it would take me slightly longer to dig through boxes of parts to find an LM317.

In any case, I share this tale for four reasons. First, it might help a younger designer avoid the same specific mistake: a diode will not drop much forward voltage when operating at relatively low current. But second, the larger picture: be sure to do your design analysis for all of the conditions which could exist in your circuit or system. And third, have some way to remind you of (and prevent) your old mistakes. It is nearly impossible to learn from success, so keep and study your failures.

The fourth reason to share this tale is to help keep me grounded and humble. No matter how much advice or wisdom I may try to share with others, sometimes I am the idiot in the story. We are all human, which should keep us striving to get better every day.